LEDs, for example, are quite susceptible to temperature-related damage - the risk of this is significantly reduced with vapor phase soldering. Which means that fine-pitch structures as well as sensitive and expensive components can also be reliably soldered.

In addition, it is easy to control and uniform. This process has an extremely high heat transfer coefficient and is therefore well suited for components with a high thermal mass. The focus below is on one of the latest reflow soldering technologies: vapor phase soldering. Hot air stations are often used by smaller labs and in the maker scene because they are very flexible and compact. It is therefore often marketed as a "rework station". However, the hot air station is extremely well suited for the post-processing of individual components, as they can be heated in a targeted manner. Both overheating and colder zones can also occur when using a hot air station. Colder areas can also occur in the "shadow" of larger components. Infrared soldering is also popular, but unfortunately it is of limited suitability for temperature-sensitive components, as these can overheat. Nevertheless, the process is worthwhile for large quantities. However, the energy requirement and thus also the energy costs are high. They offer precision and enable high throughput.

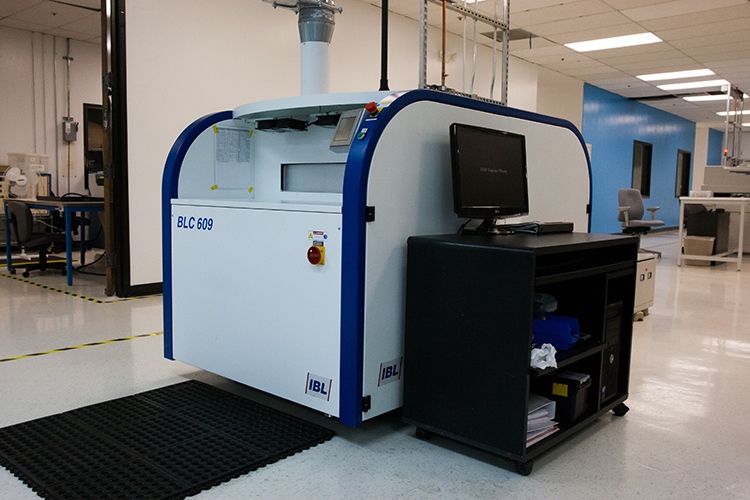

VAPOR PHASE REFLOW FULL

In industry, there are often full convection systems that heat the PCB with hot air.

VAPOR PHASE REFLOW HOW TO

How to choose the optimal reflow soldering process for your use-case. Various reflow soldering processes are available for heating the circuit board.įigure 1: The solder paste is printed on the circuit board. The components are soldered onto the printed circuit board after the soldering paste has cooled down. The subsequent heating of the assembled printed circuit board then ensures that the soldering paste melts evenly. The assembly can be done using an automatic assembly machine ("pick-and-place machine") or manually. In addition to the soldering process, the quality and correct application of the soldering paste largely determines the qualitative soldering result. The solder paste typically consists of tin balls and flux. For example, fully automatic dispensers or a screen-printing process are used. In industry, the soldering paste is preferably applied using a paste printer. The printed circuit board is then assembled and heated. The special feature of reflow soldering is that the solder paste is applied first. Reflow soldering processes, like e.g., vapor phase soldering, are considered standard soldering processes for the SMD components.

0 kommentar(er)

0 kommentar(er)